Geotubes, also known as geotextile tubes, are an innovative tool used in dredging projects. Geotubes are a relatively simple, cost-effective way to remove sediment from water.

Dredging is the process of extracting sediment and debris from the beds of waterways. Environmental workers use specialized equipment known as dredges that create a vacuum to suck up and pump out the excess sediment. Large and small water bodies benefit from dredging, including the ocean, rivers, lakes and streams.

The dewatering stage of dredging involves removing water from the sandy or rocky sediment so only solid particles remain, and that’s where geotubes come in.

Waterways need regular dredging because, with time, sand and silt wash downstream and collect in waterway bottoms, reducing their depth and posing a potential hazard to passing ships. Dredging maintains or increases the depth of bodies of water to ensure ships can safely navigate them.

Dredging also reduces fish, wildlife and human exposure to contaminants and prevents the spread of those contaminants to nearby waterways.

What Is a Geotube?

Aptly named to reflect their shape, geotubes are tube-shaped bags that environmental workers install along the shorelines of water bodies. Geotubes are an integral part of the dewatering stage of dredging — the process of isolating and retaining solids while releasing clear water back into the waterway.

Engineers build the walls of geotubes with a strong yet permeable fabric that allows water to drain out while holding onto particulate matter. In addition to dewatering dredged slurry, geotubes are instrumental in protecting shorelines and building dikes, breakwaters and islands.

How Do Geotubes Work?

We’ve explained that geotubes are used to pull sediment from water, but how exactly do they do it? Managing waterways with geotubes involves three steps — filling the tubes, dewatering the contents and consolidating the remaining sediment. Let’s dive into the details of each step.

1. Filling the Geotube With Dredged Material

A pump within the body of water being dredged hydraulically or mechanically fills the geotube with dredged material. This material is commonly known as sludge or slurry and consists of water mixed with sand or dirt, depending on the type of waterway.

Once inside the geotube, the sludge is treated with environmentally-safe polymers via a polymer-injecting system. These agents speed up the dewatering process by binding the solids together and separating them from the water.

2. Dewatering the Dredged Material

Through gravity, the particulate debris settles in an even layer at the bottom of the geotube. The newly sediment-free water rises to the top and drains out of the specially engineered fabric, leaving the solids behind and greatly reducing volume. This process occurs continuously until the geotube eventually fills with sediment.

The water that geotubes release, known as effluent, is typically clear and can often flow back to the waterway without treatment.

3. Consolidating the Remaining Sediment

Once the geotube has reached capacity, the solids will continue to densify through desiccation as the remaining moisture evaporates through the fabric.

Workers can remove the solids from the tube and keep them on-site, haul them to a landfill for disposal or transport them to another area in need of land nourishment.

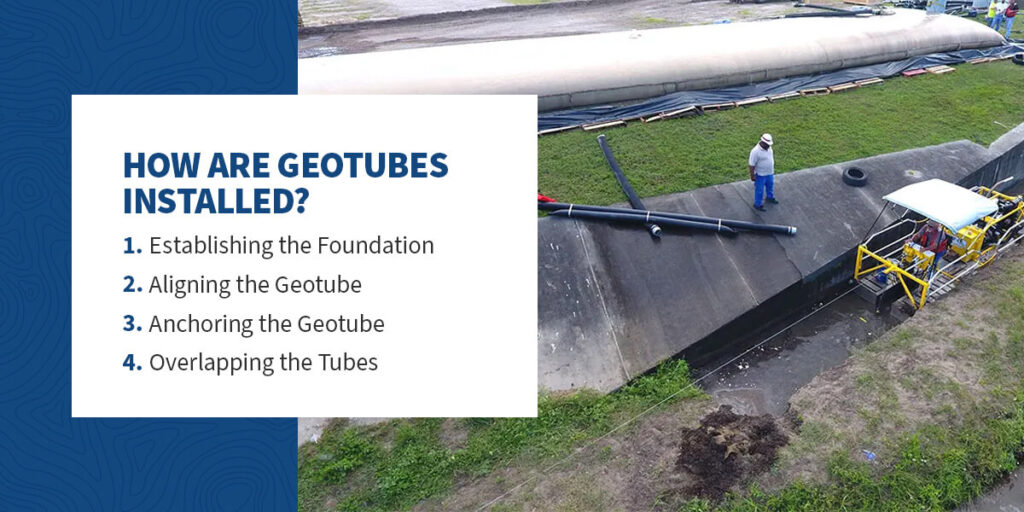

How Are Geotubes Installed?

Geotube installation requires a solid foundation, followed by proper tube alignment, anchorage and overlap.

1. Establishing the Foundation

The ground below the geotube and its protective underlayer, known as a scour apron, must be solid, level and free of sticks, stones and other protrusions that could tear the fabric. Ensure the site has been cleared and graded before placing the geotube on it.

2. Aligning the Geotube

Geotubes should be positioned properly in relation to the rest of the dredging site. You can align and secure a geotube using straps, cradles or physical supports.

Filled geotubes should reach an effective height within 150 millimeters of the specified elevation. Effective height is the distance between the existing foundation and the average top of the filled tube.

If any discrepancy exists between the top of the filled tube and the specified height, it should be corrected by filling the geotube with additional dredged material or replacing the tube if it’s been compromised. However, remember that filling geotubes above the manufacturer’s specified height can cause the structure to fail.

3. Anchoring the Geotube

The primary geotube and scour apron should be laid out on site in proper alignment and anchored in place to ensure they stay put when the geotube is filled. Anchor tubes are placed along the edges of the scour apron to secure the main tube to the foundation.

It’s important not to fill any portion of the geotube until the entire tube has been anchored to the foundation. Geotubes typically allow alignment deviations of plus or minus 600 millimeters.

4. Overlapping the Tubes

The end joints of geotubes should overlap or otherwise attach so no gaps exist between tubes. Beneath the geotube, the scour apron edges should also overlap to ensure the tube fabric doesn’t come in contact with the ground.

Which Industries Use Geotubes?

Various industries use geotube systems to manage their water, including the following:

- Agriculture, including dairy, poultry and hog waste management

- Marine remediation, including lakes, rivers, ponds, canals, channels and inlets

- Revetments, dykes, groins and breakwaters

- Shoreline protection

- Land reclamation

- Island and wetlands creation

- Power and utility

- Pulp and paper mills

- Wastewater treatment plants

- Mining and mineral processing

- Construction platforms

- Offshore structures

What Are the Advantages of Using Geotubes?

Geotube sludge dewatering containers are highly advantageous to dredging operations. Check out some of the features below:

- They boast a high flow rate that reduces volume and retains solids.

- They discharge clear water that can often be returned to the waterway and recirculated through the system.

- They’re customizable, allowing you to save costly and finite land space.

- They can be stacked on top of each other or placed in mobile containers, perfect for project sites with limited workspace.

- They’re easy to empty and remove from the site.

- They’re efficient, versatile and environmentally friendly.

- They’re made of a strong textile that can withstand all weather conditions.

- They help reduce operational safety risks.

- They’re cost-effective and easy to maintain.

Turn to GeoForm International for Effective Dewatering Technology

If you’re looking for an efficient and timely method of removing sediment and buildup from a body of water, GeoForm International has the products to get the job done. We develop and provide high-quality dredging equipment, including dredges, dredge systems, submersible pumps and geotubes. Additionally, we offer dredge operation training, small dredge rentals, replacement parts and equipment repairs.

Contact GeoForm International today for dredging knowledge, project management and simple solutions. We look forward to partnering with you!